Factory workers do the hard work of making the products and goods that we all use. Despite advances in safety technology and laws that require employers to take precautions, factory workers are still at risk of injuries from the machinery and equipment they operate as well as from dangerous chemicals and other hazards in the workplace. When a factory worker is injured on the job, he or she may be entitled to workers’ compensation benefits including paid medical care, partial replacement of lost wages, and pain and suffering.

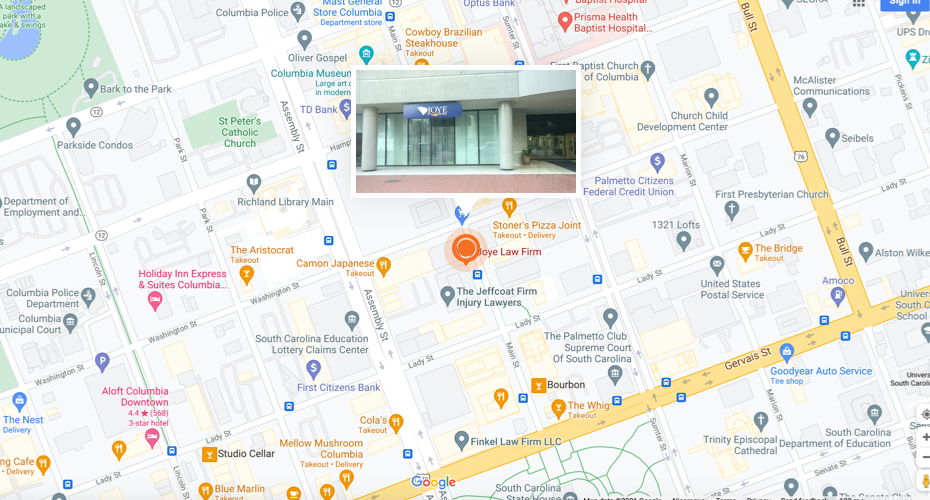

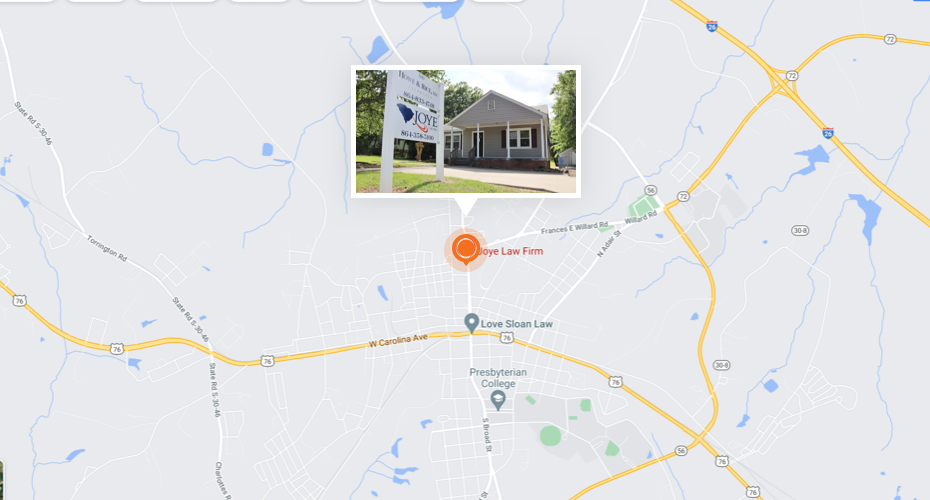

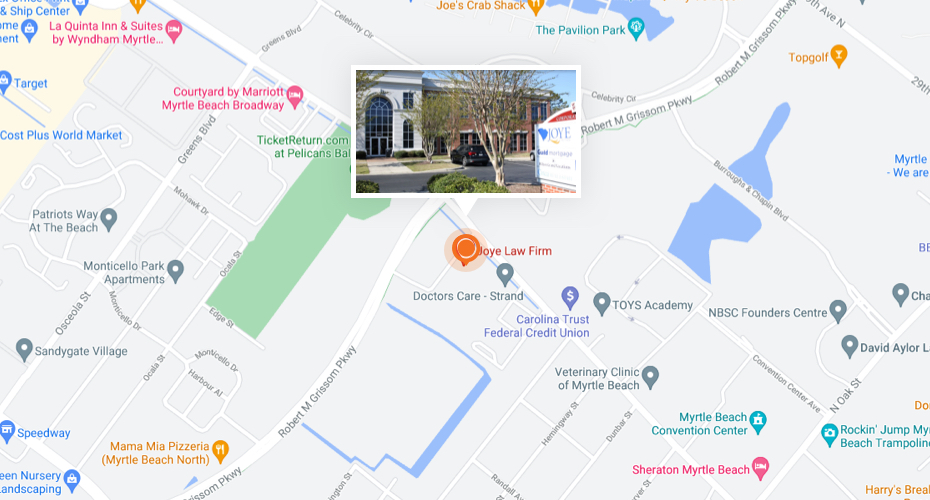

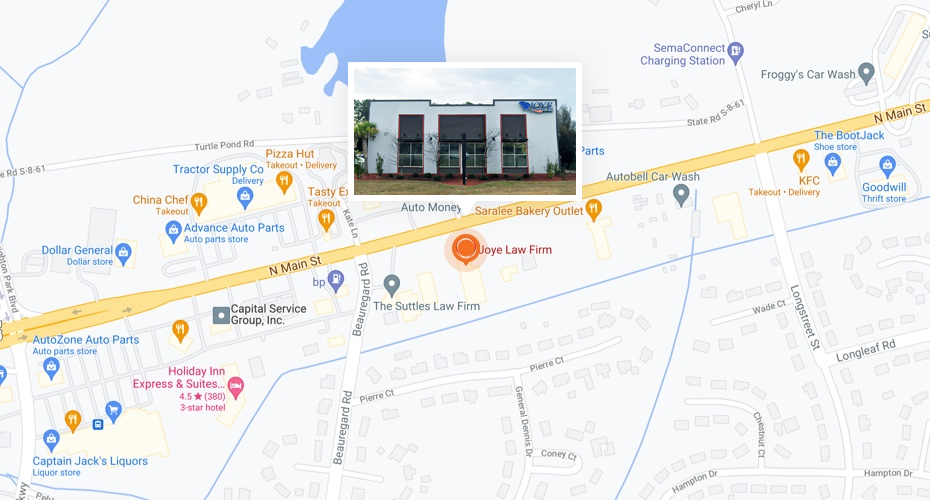

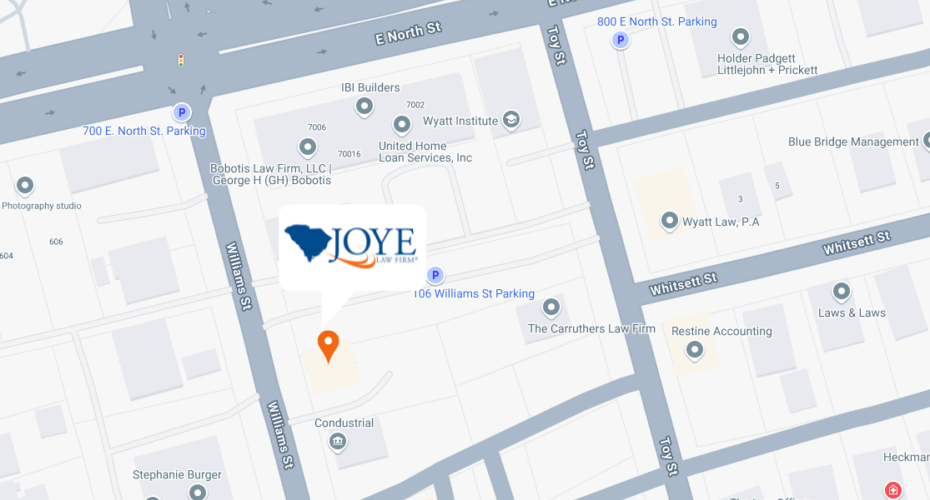

Since 1968s, the factory injury attorneys of Joye Law Firm have helped injured workers in South Carolina obtain the full benefits provided by law. From our offices in Charleston, North Charleston, Columbia, Myrtle Beach, Summerville, and Clinton, our attorneys have helped factory workers across South Carolina move forward with their lives after suffering life-changing injuries on the job.

Our attorneys at Joye Law Firm have more than 300 years of collective experience, with both of our partners recognized by Super Lawyers. Our firm takes pride in our track record of success. We’ve obtained millions of dollars in compensation for our factory worker clients, regularly securing six-figure settlements and awards for injured workers.

If you or a loved one has suffered an injury in a factory, contact Joye Law Firm today to schedule a free consultation with one of our knowledgeable attorneys. There is no obligation to you – when you hire us for your case, we do not get paid unless you do.

Common Reasons for Factory Workers’ Injuries

Even with safety procedures in place, factories can be a dangerous space for factory workers. Below are some of the reasons for factory worker injuries our South Carolina factory injury lawyers commonly see.

Dangerous machinery

Factory machinery and equipment often has many moving parts that are sharp. Equipment and machinery can be dangerous if factory workers are not properly trained in the use of the equipment and machinery and in the proper safety procedures to follow. Equipment and machinery that is defectively designed or manufactured also may cause an injury. A piece of unsafe equipment that causes an injury as a result of a design defect may be the basis of a lawsuit after a factory worker injury.

Forklifts

Forklifts are used in many factories to move materials. Forklift accidents cause injuries to more than 20,000 workers a year in a wide range of work sites, according to the Occupational Health and Safety Administration. Forklift operators are required to have the training to operate the vehicles. Those who drive too fast may be unable to avoid hitting a factory worker who steps suddenly in their path. Forklift accidents are a risk, especially when factories allow workers to operate forklifts without the required training. The operators of forklifts can be injured in a collision or tip-over accident when they fail to use seatbelts and other safety equipment on the forklift.

Slip/trip and fall accidents

Slip/trip and fall accidents can happen at factories for many reasons. Machinery or equipment may leak fluids. Stored fluid containers can be knocked over and spilled. Water or snow can be tracked in from the outside and create slick floors. Boxes can be left in hallways and other pathways in the factory. A factory worker who isn’t suspecting that there is a slip or trip hazard can easily suffer a serious accident.

Heavy objects

Factory workers are often required to lift and carry heavy objects, equipment, and materials, which can cause stress injuries. Workers can be injured in a crush accident when heavy objects or equipment fall on them.

Repetitive motions

Many tasks in a factory require a worker to make the same physical motions hundreds or thousands of times over the course of a workweek. This type of work leaves the factory worker at risk of repetitive stress injuries such as carpal tunnel syndrome. Repetitive stress injuries develop gradually, but they can be debilitating and require surgery.

Occupational illnesses

Some factory workers are exposed to hazardous and toxic substances in the course of their work, including chemicals, fumes, or dangerous materials such as asbestos, dust, or radioactive materials. These materials and substances can cause a worker to suffer a life-threatening occupational disease. Unfortunately, some diseases and illnesses develop many years after the worker’s exposure to hazardous substances or materials, making it harder to identify the cause. For example, cancer-related to workplace asbestos exposure typically develops 20 to 30 years after the exposure.

Explosions and fires

When workplace safety protocols are ignored, factories that have combustible materials on site are more likely to have fires and explosions. Workers caught in explosions and fires can suffer life-threatening burns and permanent disfigurement. Workers who have severe burns may require skin grafts and cosmetic surgery.